What Is a Fogging Test?

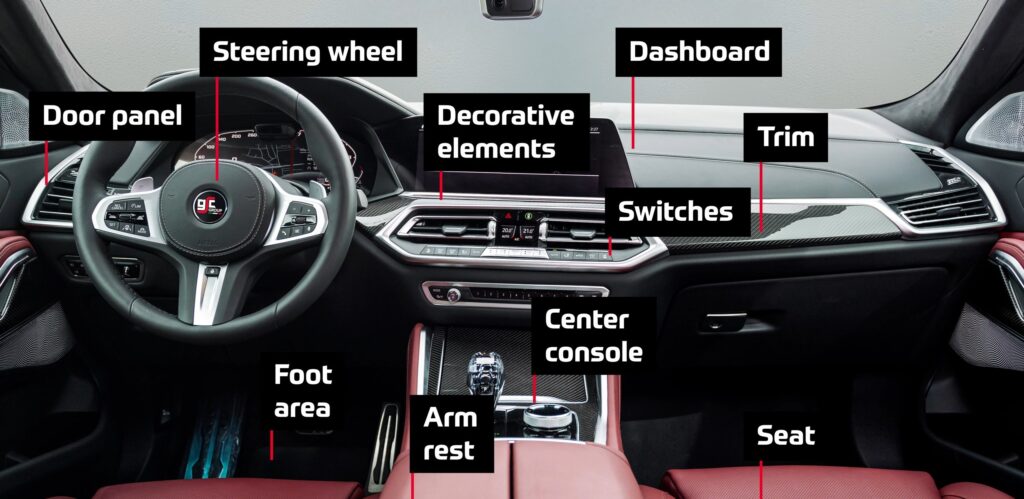

Fogging test is a critical quality test for automobile interior materials, especially automobile carpets.

This test checks how much volatile substance is released from the carpet when exposed to heat. These vapors can condense on vehicle glass and create a foggy layer, which reduces visibility and affects driver safety.

At SAB Labs Karachi, we provide professional fogging testing services according to international automotive standards.

Why Fogging Test is Important for Automobile Carpets

Automobile carpets are placed inside closed vehicle cabins. When the car heats up, especially in hot

climates like Pakistan, carpets can release vapors.

Fogging test helps to:

- Ensure passenger safety

- Meet OEM and export requirements

- Improve interior air quality

- Avoid customer complaints

International Standards for Fogging Test

At SAB Labs Karachi, we perform fogging tests according to recognized global standards:

- DIN 75201 (Most common automotive standard)

- ISO 6452

- SAE J1756

These standards are accepted by automotive manufacturers worldwide.

Fogging Test Methods

There are two main fogging test methods:

1. Gravimetric Method

This method measures the weight of condensate deposited on an aluminum foil or glass plate.

- Result is measured in mg

- Commonly used for carpets and interior trims

2. Reflectometric Method

This method measures the loss of light reflectance on a glass surface.

- Result is shown as percentage fogging

- Indicates visual clarity loss

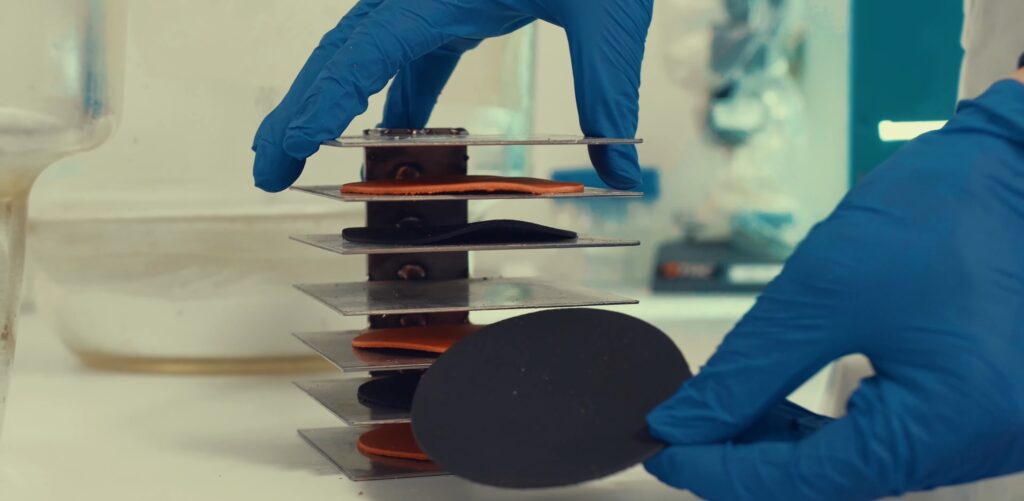

Fogging Test Procedure (Step by Step)

Below is the standard fogging test procedure followed at SAB Labs.

Step 1: Sample Preparation

The purpose of sample preparation is to make sure that the test sample truly represents the actual

automobile carpet used in vehicles. If the sample size or condition is incorrect, the fogging result will not

reflect real performance.

What is the Standard Sample Size?

According to common automotive fogging standards (such as DIN 75201), the carpet sample is usually cut into a circular or square shape with a defined surface area. In many cases, the standard size is 80 mm

diameter or an equivalent area specified by the standard or customer requirement.

Sample Preparation Procedure

First, we review the applicable test standard or OEM requirement. – Based on the standard:

- We identify the required sample size

- We then cut the automobile carpet precisely according to this defined size

- The sample is cleaned to remove dust or loose fibers

- The sample is conditioned at laboratory temperature to stabilize it.

- Finally, the initial weight of the sample is recorded.

Step 2: Test Setup

The purpose of test setup is to create controlled conditions that closely simulate the interior of a vehicle

cabin. This ensures repeatable and reliable test results.

What Equipment Is Used?

A fogging test chamber is used. It consists of a heated sample holder and a cooled glass plate or aluminum

foil placed above the sample.

Test Process Step by Step

- First, the prepared carpet sample is placed inside the fogging test chamber.

- A clean glass plate or aluminum foil is fixed above the sample at a specified distance. This glass plate represents

the vehicle windshield or window. - The chamber lid is closed properly to avoid vapor leakage.

- The test temperature is set, usually 100°C ± 2°C, as defined by the standard.

Step 3: Heating Phase

The purpose of the heating phase is to simulate real vehicle conditions when a car is parked under sunlight.

During this time, interior materials heat up and release volatile substances.

What Happens During Heating?

When the carpet is exposed to high temperature, plasticizers, oils, and other volatile compounds start to

evaporate.

Heating Phase Process

- The chamber is heated to the set temperature.

- The sample is maintained at this temperature for a defined time, usually 3 hours.

- During heating, volatile organic compounds (VOCs) are released from the carpet.

- These vapors move upward inside the closed chamber.

Step 4: Condensation Phase

The purpose of the condensation phase is to observe how released vapors behave when they come into

contact with a cooler surface, similar to vehicle glass.

Why Condensation Is Important:

In real cars, vapors released from carpets condense on windshields and windows, causing fogging that

reduces visibility.

Condensation Process Step by Step

- The vapors released from the heated carpet rise inside the chamber.

- When these vapors reach the cooler glass plate, they condense on its surface.

- A visible or measurable fog layer forms on the glass. – This directly simulates windshield fogging inside a vehicle

Step 5: Measurement and Evaluation

The purpose of measurement and evaluation is to quantify the fogging effect and determine whether the

automobile carpet meets acceptance criteria.

How Measurement Is Done:

The measurement method depends on the selected fogging test type (gravimetric or reflectometric).

Measurement Process Step by Step

- The glass plate is carefully removed from the chamber. – For the gravimetric method, the glass plate is weighed before and after the test.

- The difference in weight represents the amount of condensed material. – For the reflectometric method, light reflectance of the glass is measured.

- The fogging value is calculated and recorded.

- Results are compared with standard or customer limits

Acceptance Criteria

Each automobile manufacturer sets its own fogging limits. Typical acceptable values:

- Gravimetric fogging: ≤ 2.0 mg

- Reflectometric fogging: ≥ 60–70% clarity

Common Causes of High Fogging in Carpets

- Low-quality raw materials

- Excessive plasticizers

- Poor adhesive formulation

- Improper curing process

Testing helps identify these issues early.

Why Choose Sab Labs Karachi?

SAB Labs is a trusted testing laboratory in Karachi, offering accurate and reliable fogging tests.

Our Strengths

- Experienced technical team

- International standard equipment

- Fast turnaround time

- Detailed test reports

- Support for exporters and manufacturers

We help you meet automotive compliance with confidence and as per standard requirements.

Industries We Serve

- Automobile carpet manufacturers

- Auto parts suppliers

- Exporters

- OEM vendors

- Quality control departments

Contact Sab Labs Karachi

For fogging test services and quotations, contact us today.

Location: Karachi, Pakistan

Laboratory: SAB Labs

Service: Fogging Test for Automobile Interior Materials